- หน้าแรก

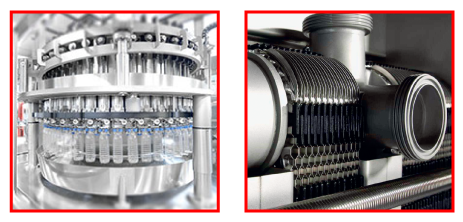

- สินค้า

-

ข่าวสาร

ข่าวสารล่าสุด

-

ประกาศรับสมัครงาน 2 ตำแหน่ง

2023-07-17 16:59:58 -

ภาพบรรยากาศร่วมออกงานแสดงสินค้า Propak Asis 2023

2023-06-09 15:41:48 -

ประกาศรับสมัครงาน

2021-03-23 16:24:49

-

-

บทความ

บทความล่าสุด

-

Rotary Lobe Pump คืออะไร

2021-02-23 10:36:58 -

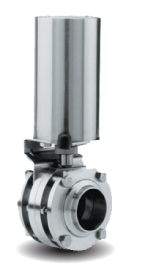

ลักษณะของวาล์วแต่ละชนิด และการเลือกใช้งานอย่างเหมาะสม

2020-07-02 09:24:59 -

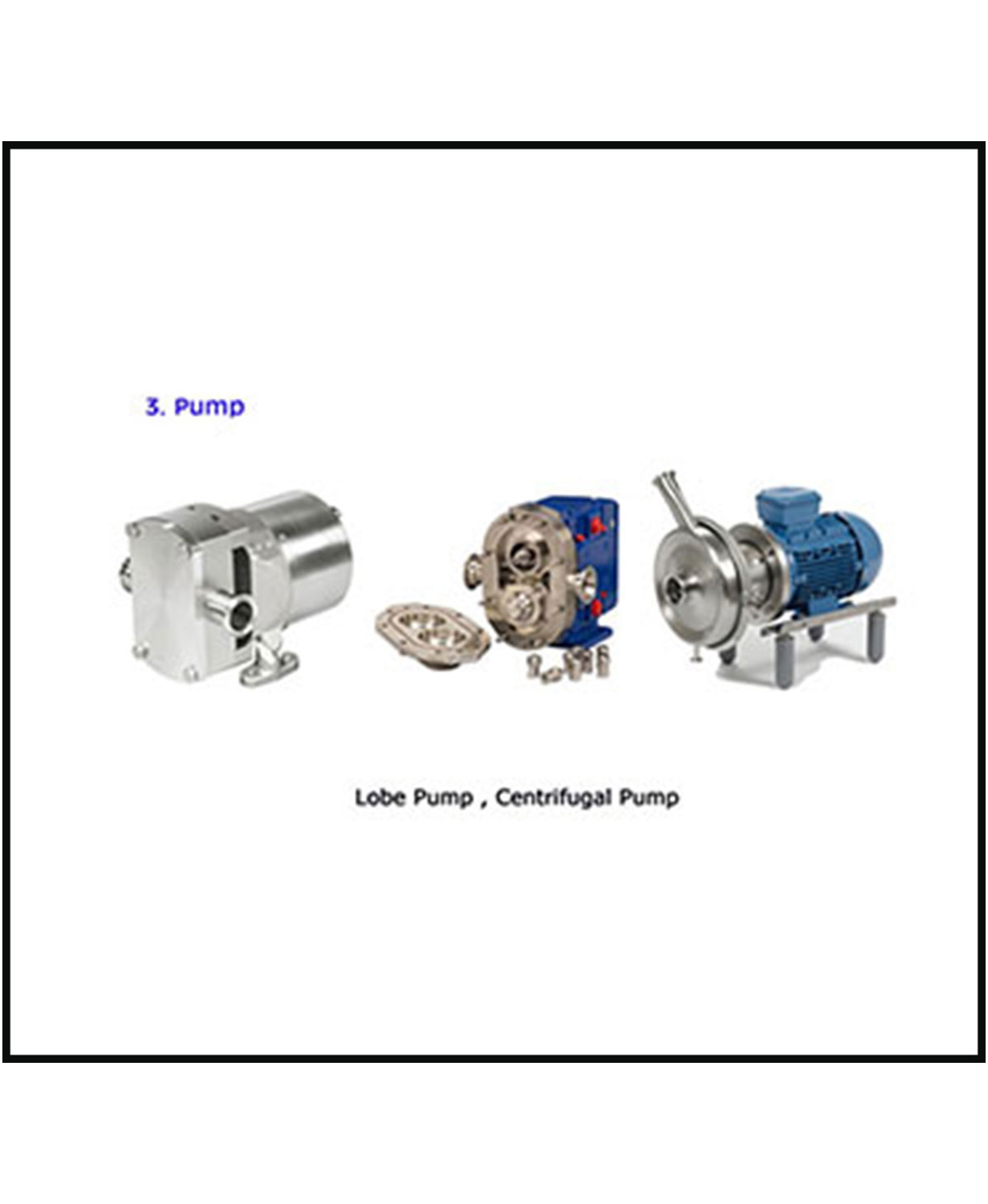

รูปแบบของปั๊มและการเลือกใช้งาน

2020-07-02 09:16:04

-

- อีบุ๊ค

- เกี่ยวกับเรา

- พรีเซ็นเทชั่น

- ติดต่อเรา

จันทร์ - เสาร์ 08:00 - 17:00 น.